Description

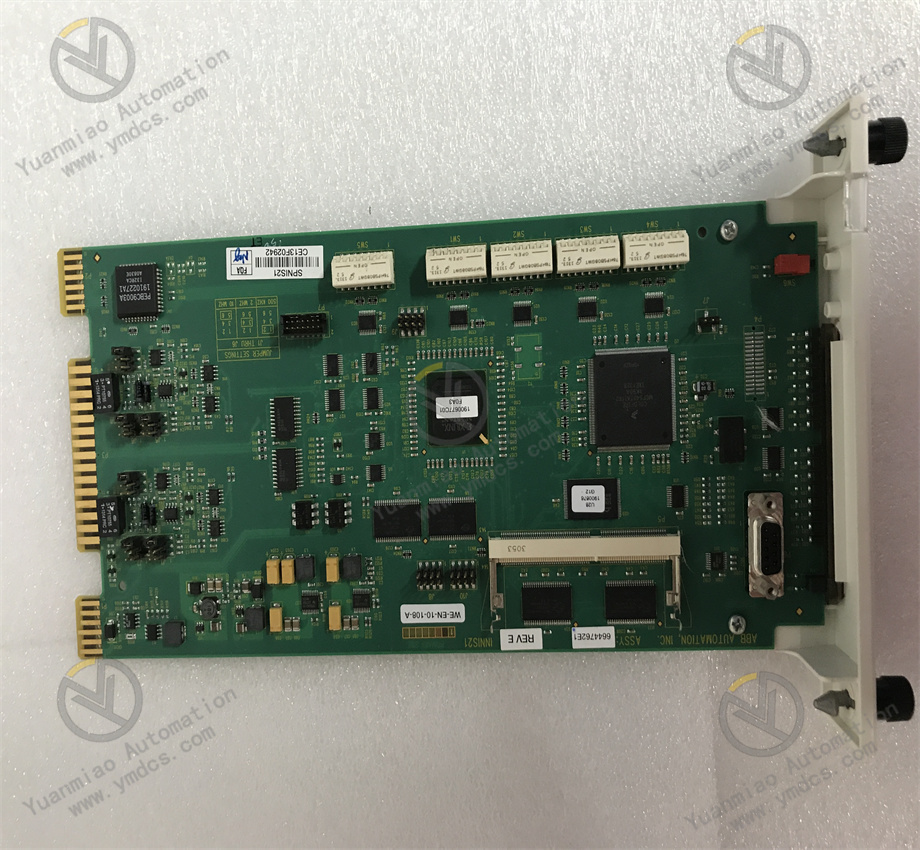

ABB DO890 3BSC690074R1

I. Overview

ABB DO890 3BSC690074R1 is an intrinsically safe 4-channel digital output module, positioned as a Precision Drive and Safety Control Terminal for Hazardous Areas. It is a component of the S800 I/O series under the ABB Ability System 800xA Distributed Control System (DCS). Integrated with an intrinsically safe interface, this module can directly connect to process equipment in Zone 0, Zone 1 or Zone II hazardous areas without additional external safety devices. It stably receives digital control commands issued by ABB control systems such as Advant 800xA, and converts the commands into intrinsically safe output signals through its internal high-side switch drive circuit and full-channel isolation design, realizing start-stop control and status switching of intrinsically safe executive devices including Ex-certified solenoid valves, alarm sounders and indicator lights. With its excellent intrinsic safety performance and anti-interference capability, it provides safe and reliable signal output support for industries with flammable and explosive risks such as oil and gas, chemical processing, pharmaceuticals, mining and mineral processing, ensuring the stable operation of industrial process automation in hazardous areas.

II. Product Features

Intrinsically Safe Core Design: The module integrates an intrinsically safe interface and has obtained intrinsic safety certifications such as IECEx and ATEX. It can be directly deployed in hazardous areas including Zone 0, Zone 1 and Zone II without additional external intrinsically safe protection devices such as safety barriers. It can directly connect to intrinsically safe executive devices in hazardous areas, eliminating safety risks in flammable and explosive environments from the source.

Full-channel Isolation and Stable Drive Performance: It adopts a 4-channel independent design. All channels are galvanically isolated from each other, as well as from the ModuleBus and power supply, effectively avoiding signal interference between channels and ensuring the reliability of signal transmission in noisy industrial environments. Each channel can provide a nominal current of 40mA, capable of stably driving field intrinsically safe devices with a load impedance ≤ 300Ω. The output stage power supply is converted from 24V voltage, and combined with built-in EMC protection components, it can effectively resist on-site voltage fluctuations and electromagnetic interference, ensuring the stability and accuracy of output signals.

Flexible System Adaptability and Installation Design: Tailor-made for the ABB 800xA Distributed Control System, it can seamlessly connect with control systems such as Advant 800xA. It supports adaptive installation with Compact MTU terminal units such as TU890 and TU891, enabling two-wire connection with process equipment without additional terminals, meeting the wiring requirements of different application scenarios including explosion-proof and non-explosion-proof. Its compact structure and lightweight design make it suitable for installation scenarios with limited cabinet space in hazardous areas, simplifying on-site deployment processes.

Comprehensive Fault Diagnosis and Status Feedback: Built-in with full-channel open-circuit and short-circuit detection functions, it can real-time monitor the working status of each channel. When a fault is detected, it automatically generates a fault signal and uploads it to the controller via ModuleBus. Equipped with independent channel output status and fault status LED indicators, operation and maintenance personnel can intuitively judge the working condition and fault type of a single channel through the indicators, quickly locate fault points, and reduce the operation and maintenance difficulty and working time in hazardous areas.

Reliable Environmental Adaptability and Safety Protection Performance: It has passed strict intrinsic safety and electromagnetic compatibility certifications, with strong anti-interference capability and environmental adaptability. It can operate stably in a wide temperature range of -40℃~+70℃, adapting to hazardous area scenarios under different climatic conditions. The working humidity adaptation range is 0%~95% (no condensation), capable of resisting the impact of humid environments on module performance. The overall protection design of the module can effectively cope with harsh conditions such as dust and vibration in hazardous areas, ensuring the safe and stable operation of the core circuit.

- Convenient Operation and Maintenance and Firmware Upgrade Support: The standardized ModuleBus interface and terminal unit adaptive design simplify the wiring and module replacement process. It supports firmware version updates, which can be completed through dedicated configuration software to obtain the latest functions and fault repair support, improving the long-term operation reliability and compatibility of the module.

III. Technical Parameters

1. Core Basic Parameters

- Product Model: ABB DO890 3BSC690074R1

- Product Type: Intrinsically Safe 4-channel Digital Output Module

- Manufacturer: ABB Group

- Product Series: ABB Ability System 800xA DCS S800 I/O System Component

- Core Functions: Receive digital commands from the controller, intrinsically safe signal output, full-channel open/short-circuit detection, fault diagnosis and status feedback, intrinsic safety protection

- Communication Method: Communicate with the controller via ModuleBus, compatible with the S800 I/O system bus protocol

- Applicable Systems: ABB Advant 800xA Distributed Control System (DCS)

- Compatible Terminal Units: TU890 (for explosion-proof applications), TU891 (for non-explosion-proof applications)

- Intrinsic Safety Certifications: IECEx, ATEX

- Applicable Hazardous Areas: Zone 0, Zone 1, Zone II

- Application Fields: Industrial automation scenarios in hazardous areas such as oil and gas (wellhead control, pipeline transportation, refining), chemical processing (hazardous chemical reaction control, product processing), pharmaceuticals (mixing, sterilization, packaging process control), mining and mineral processing (material handling, processing equipment control).

2. Electrical Performance Parameters

- Supply Voltage: 24V DC input at the module power connection terminal; the output stage power supply is converted from this voltage

- Output Type: Digital high-side switch output, intrinsically safe

- Channel Quantity: 4 independent digital output channels; galvanic isolation is implemented between channels, and between channels and the ModuleBus as well as power supply

- Output Voltage Range: 11V DC ~ 35V DC (rated for 24V DC power supply scenarios)

- Output Current: Nominal output current of 40mA per channel; maximum drivable load impedance ≤ 300Ω

- Fault Diagnosis Range: Channel open circuit, channel short circuit, ModuleBus communication abnormality, power supply abnormality

- Special Functions: Intrinsic safety protection, full-channel independent isolation, open/short-circuit detection for each channel

- Insulation Performance: Full-channel galvanic isolation; rated insulation voltage complies with intrinsic safety certification standards

- Driven Device Type: Intrinsically safe executive devices such as Ex-certified solenoid valves, intrinsically safe alarm sounders, intrinsically safe indicator lights.

3. Environmental and Physical Parameters

- Operating Temperature: -40℃ ~ +70℃

- Storage Temperature: -40℃ ~ +85℃

- Relative Humidity: 0% ~ 95% RH (no condensation)

- Pollution Degree: Degree 2 (compliant with IEC 60664-1 standard)

- Electromagnetic Compatibility: Compliant with EN 61000-6-2 (immunity) and EN 61000-6-4 (emission) standards

- Protection Grade: IP20 (module itself, compliant with IEC 60529 standard)

- Corrosion Resistance: Compliant with ISA-S 71.04 G3 standard

- Safety Certifications: Compliant with IEC 61131-2 standard; Intrinsic safety certifications: IECEx, ATEX

- Weight: Approximately 1000g (module itself)

- Installation Method: Rack-mounted installation (compatible with S800 I/O system standard racks)

- Process Side Connection: Jack panel connection method

IV. Working Principle

The core working principle of the ABB DO890 3BSC690074R1 is a closed-loop workflow of Safe Command Transmission - Intrinsically Safe Signal Conversion - Precision Drive - Full Status Monitoring - Fault Safety Response. Through the coordinated operation of the intrinsic safety protection unit, communication unit, signal processing unit, channel drive unit and fault diagnosis unit inside the module, it realizes accurate conversion of controller commands and reliable drive of executive devices in hazardous areas while ensuring intrinsic safety. The specific working process can be divided into five core stages:

Stage 1: System Initialization and Parameter Configuration StageAfter the module is installed and connected to the S800 I/O system, it establishes a communication connection with the 800xA controller via ModuleBus, automatically completes initialization and startup, performs internal circuit self-test, calibrates 4 output channels one by one, detects the status of the intrinsic safety protection circuit, and verifies the integrity of the communication link. Operation and maintenance personnel complete the configuration of basic parameters such as channel fault detection thresholds and output response parameters through the system configuration software, ensuring the module is precisely adapted to the controller and intrinsically safe executive devices in hazardous areas, and meeting the safe operation requirements of hazardous area control scenarios.

Stage 2: Controller Command Receiving StageBased on the logic operation results of the industrial process in hazardous areas, the controller transmits digital control commands (such as start-stop commands for intrinsically safe solenoid valves, trigger commands for alarm devices) to the communication unit of the DO890 module via ModuleBus. The communication unit parses the command format and verifies validity, filtering invalid commands and interference signals to ensure the accuracy and safety of command transmission, avoiding safety risks in hazardous areas caused by incorrect commands.

Stage 3: Intrinsically Safe Signal Conversion and Drive Preparation StageThe verified control commands are transmitted to the signal processing unit inside the module. The processing unit converts the commands into standardized drive signals, and at the same time triggers the intrinsic safety protection unit to condition the signals, ensuring the output signals meet the requirements of intrinsic safety specifications. The drive signals are then transmitted to the high-side switch circuit of the corresponding channel, preparing for subsequent output drive. Meanwhile, the module real-time monitors its own power supply status to ensure stable power supply, preventing the impact of power supply fluctuations on intrinsic safety performance.

Stage 4: Channel Output Drive and Status Collection StageThe conditioned intrinsically safe drive signals are transmitted to the intrinsically safe executive devices in hazardous areas through the corresponding output channels, providing a nominal working current of 40mA for the devices and triggering the devices to complete preset actions (such as solenoid valve opening, alarm sounding). Meanwhile, the module real-time collects the output current signal of each channel through the built-in current detection circuit, monitors whether the channel has abnormal states such as open circuit or short circuit, and provides real-time and accurate data support for fault diagnosis.

V. Common Fault Troubleshooting

1. No Signal Output/Output Abnormality in Partial/All Output Channels

2. Module Reports Channel Open Circuit/Short Circuit Fault (Fault Light On)

3. Abnormal Communication Between Module and Controller

4. Module Fails to Start/Power Indicator Has No Response