Description

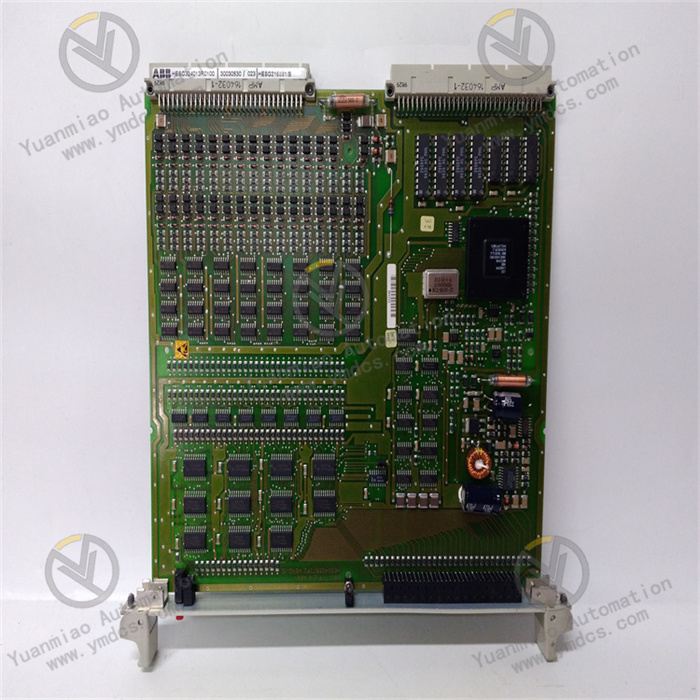

ABB AO890 3BSC690072R1

I. Overview

ABB AO890 3BSC690072R1 is an intrinsically safe analog output module, originally manufactured in Sweden. Its core function is to accurately convert digital signals from the control system into standard analog signals, achieving reliable control of process equipment in hazardous areas. It is widely used in industrial scenarios with flammable and explosive risks such as petrochemicals, natural gas extraction, and coal chemical industry.

II. Product Features

Intrinsically Safe Design: Each output channel is equipped with an independent intrinsically safe protection component, complying with relevant intrinsically safe standards. It can be directly connected to process equipment in hazardous areas without additional safety isolation devices, eliminating potential safety hazards in hazardous environments from the source.

Multi-channel Independent Output: It has 8 independent analog output channels, and each channel can stably output 0(4)-20mA standard current signals, meeting the control requirements of multiple field actuators simultaneously and adapting to the coordinated control of multiple devices in complex industrial scenarios.

Reliable Electrical Isolation: The module has a dedicated isolation zone inside, realizing complete electrical isolation between the input side and the output side. It can effectively block direct current conduction, prevent the spread of electrical faults, improve the electromagnetic compatibility of the module, and reduce the impact of electromagnetic interference on signal transmission.

Flexible Compatibility and Matching: It can be directly paired with TU890 explosion-proof MTU and TU891 non-explosion-proof MTU. Signal interaction with process equipment can be completed through two-wire connection without additional terminal configuration, adapting to application scenarios with different explosion-proof grades.

Overload Protection Function: It has a complete overload protection mechanism. Under normal working conditions, each channel can drive a loop current of up to 20mA to the field load. When an overload occurs, the current will be automatically limited to 22mA to avoid damage to the module and field equipment due to overload.

- Convenient Integration and Deployment: Adopting a standardized design, it has excellent compatibility with ABB related control systems and supporting components. The installation process is simple, the wiring operation is fast, the system integration and expansion can be completed quickly, and the cost of on-site deployment and later maintenance is reduced.

III. Technical Parameters

1. Core Basic Parameters

- Product Model: AO890

- Order Number: 3BSC690072R1

- Product Type: Intrinsically Safe Analog Output Module

- Manufacturer: ABB

- Place of Origin: Sweden

- Weight: Approximately 1000g

2. Output Performance Parameters

- Number of Channels: 8 independent analog output channels

- Supported Signal Type: 0(4)-20mA standard current signal

- Rated Output Current: 20mA

- Overload Protection Current: 22mA (Automatic Limitation)

3. Core Protection and Compatibility Parameters

- Protection Type: Intrinsically Safe Protection (Independent for Each Channel), Electrical Isolation Protection

- Compatible Matching Units: TU890 Compact MTU (for Explosion-proof Applications), TU891 Compact MTU (for Non-explosion-proof Applications)

- Connection Method: Two-wire Connection, No Additional Terminals Required

4. Environmental and Installation Parameters

- Operating Temperature: -20℃ to +60℃ (Adaptable Range for Conventional Industrial Environments)

- Storage Temperature: -40℃ to +85℃

- Relative Humidity: 5% to 95% (Non-condensing)

- Installation Method: Suitable for Standard Rack Mounting, Installed Cooperatively with TU890/TU891 MTUs

IV. Working Principle

The core working principle of the ABB AO890 3BSC690072R1 analog output module is "Digital Signal Reception - Isolation Conversion - Intrinsically Safe Signal Output - Status Monitoring". Through the built-in Digital-to-Analog (D/A) conversion chip, electrical isolation circuit and intrinsically safe protection circuit, it realizes safe and accurate control of equipment in hazardous areas.

The specific working process is as follows: First, through the cooperative connection with TU890/TU891 compact MTUs, the module receives digital control signals from the upper control system, which contain the target operating parameters of field actuators (such as numerical instructions corresponding to valve opening, pump speed, etc.). Then, the digital signals enter the internal electrical isolation zone of the module. On the premise of realizing electrical isolation between input and output, the D/A conversion chip converts the digital signals into preliminary analog current signals. Next, the analog signals are processed and calibrated by the intrinsically safe protection circuit, and stabilized into 0(4)-20mA current signals that meet the intrinsically safe standards, ensuring that the signal output meets the safety requirements of hazardous environments. Finally, the standardized intrinsically safe analog signals are transmitted to the corresponding field actuators through 8 independent channels, driving the actuators to operate accurately according to the control instructions.

V. Common Troubleshooting

1. No Output Signal Response / Abnormal Signal

Phenomenon: After the upper system sends a control command, there is no analog signal output from the corresponding channel of the module, or the output signal deviates from the set value, and the field actuator fails to operate or operates abnormally.

Solutions: 1. Check the connection status between the module and TU890/TU891 MTUs, re-plug and fasten the connection parts to ensure good contact. 2. Troubleshoot the faulty channels one by one. Connect the load corresponding to the faulty channel to a normal channel by substitution method. If the signal returns to normal, it indicates that the intrinsically safe protection component of the original channel is faulty, and you need to contact after-sales service for repair. 3. Check the continuity and insulation of the output line, repair the short-circuited or open-circuited line, and ensure that the line connection meets the intrinsically safe requirements. 4. Detect the power supply voltage of the module to ensure stable power supply that meets the system requirements. 5. Troubleshoot the communication link with the upper system, verify the communication parameters, and restart the communication equipment to restore the normal operation of the link.

2. Frequent Triggering of Overload Protection

3. Failure of Normal Matching Between Module and TU890/TU891 MTUs