Description

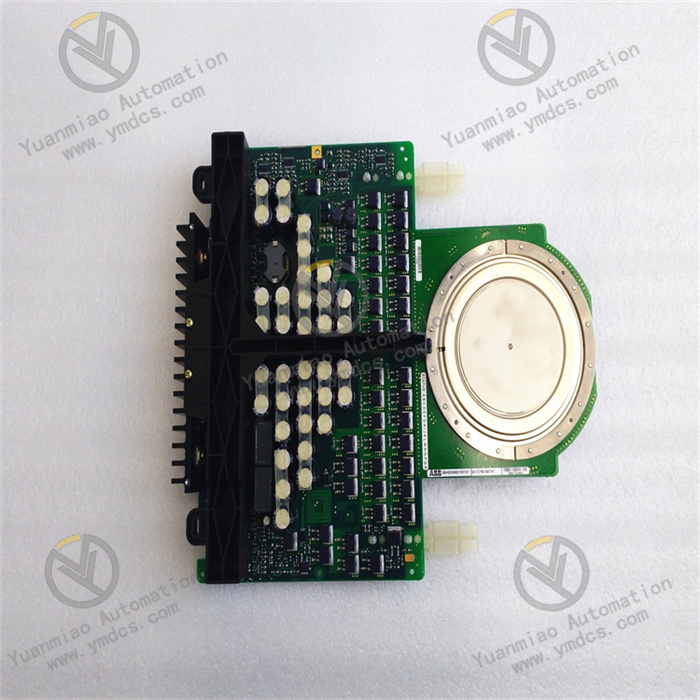

ABB PFTL101B-2.0kN 3BSE004185R1

The ABB PFTL101B-2.0kN (Order No.: 3BSE004185R1) is a medium-range high-precision tension/load cell, specifically designed for the accurate measurement of tension, pressure and weight within the 2.0kN range in industrial scenarios. As a core upgraded model in ABB's tension measurement product line, it is widely used in tension control and load metering applications across various harsh industrial environments by virtue of the unique advantages of magnetoelastic technology.

I. Working Principle and Structural Features

This sensor operates based on the magnetoelastic effect (also known as the piezomagnetic effect). Its core principle is that when mechanical force acts on the sensor's measuring assembly, the magnetic permeability of the internal material changes regularly. A dedicated detection circuit converts this change in magnetic permeability into a stable and accurate electrical signal, thereby achieving precise force measurement.

Compared with traditional strain gauge sensors, its non-contact and wear-free measurement method fundamentally solves the pain points of strain gauge sensors such as easy fatigue loss and short service life, while offering stronger anti-interference capability and long-term stability.

The sensor features a reinforced structural design as a whole, mainly consisting of three parts: a measuring assembly (FR), a force conversion assembly (FV) and a 316L stainless steel housing. The housing is hermetically sealed via laser welding, reaching an IP67 protection rating, which can effectively resist the impact of harsh environmental factors such as dust, humidity and corrosive gas, making it suitable for various severe industrial scenarios. With a compact structural design, it is a horizontal-measurement pillow block load cell that supports both horizontal and inclined installation methods. It is easy to install and highly adaptable, and can be flexibly integrated into various industrial equipment and production lines.

II. Technical Specifications

The technical specifications of this sensor are strictly calibrated, delivering excellent precision and stability. The core parameters are listed below, taking into account the authoritative calibration values from different documents to ensure accurate and referable parameters:

- Rated Load (Rated Capacity): 2.0kN (i.e., 2000N, approximately 450lbs, equivalent to 204 kilogram-force);

- Measurement Accuracy: ±0.2% of full scale (F.S.), up to ±0.25% of full scale output (FSO) in some scenarios (when powered by 220V AC); the comprehensive error is ≤0.03% F.S. (compliant with Class C3 accuracy standard);

- Nonlinearity: ±0.05% F.S.; Hysteresis: ±0.03% F.S.; Repeatability: ±0.02% F.S.;

- Creep Performance: Creep value within 30 minutes ≤±0.02% F.S.; annual drift rate ≤±0.02% F.S., with excellent long-term stability;

Output Signal: Standard analog signal is 2.0mV/V (based on excitation voltage); optional 4-20mA DC signal output (a matching signal converter is required);

- Excitation Parameters: Excitation voltage ranges from 10V DC to 15V DC (12V DC recommended), and wide voltage excitation of 12-24V DC is supported in some scenarios; maximum excitation current is 60mA, and the low-power design can reduce the overall energy consumption of the system;

- Response Performance: Response time ≤5ms; equipped with a dynamic high-speed calculation circuit, it can achieve real-time data processing at a maximum speed of 125μs and accurately capture tiny tension fluctuations (minimum detectable micro-force fluctuation is 0.5N);

- Overload Capacity: Maximum overload in the measurement direction up to 10.0kN; allowable transverse load is 30.0kN; it has an ultra-strong overload tolerance, effectively avoiding equipment damage caused by accidental overload;

Physical Characteristics: Deflection is only 0.015mm, and spring constant is 130kN/mm; it features high structural rigidity with no obvious deformation during measurement, ensuring measurement accuracy;

- Operating Environment: Operating temperature ranges from -20℃ to +80℃ (calibrated as -20℃ to +70℃ in some documents, subject to actual working conditions); IP67 protection rating, adaptable to harsh industrial environments with humidity, heavy dust and strong vibration;

- Electrical Protection: Built-in radio frequency interference filter with multiple protection mechanisms such as overload protection, short-circuit protection and open-circuit protection; it has strong anti-electromagnetic interference capability, suitable for strong electromagnetic environments such as steel mills and chemical plants;

- Other Features: Supports single-point grounding and parallel power supply, and is compatible with redundancy technology to improve system reliability; factory calibration is completed upon delivery, no on-site recalibration is required, and it can be used immediately after unboxing.

III. Product Advantages

Compared with similar sensors, this model has five core advantages relying on ABB's core technologies and optimized design, which can meet the actual needs of industrial scenarios:

- High Precision and Stability: Adopting core magnetoelastic technology combined with strict factory calibration, it features high precision, low hysteresis, good repeatability, small drift during long-term operation and a service life of up to 15 years, which can reduce the equipment replacement frequency by 60%;

- Strong Adaptability to Harsh Environments: The fully sealed stainless steel housing with IP67 protection rating and laser welding technology enables stable operation in scenarios with humidity, heavy dust, corrosive gas and strong vibration, suitable for various severe industrial environments;

- Outstanding Anti-Interference Capability: Built-in radio frequency interference filter with high-power, low-impedance AC signal output; it has strong resistance to electrical interference and ground fault, suitable for strong electromagnetic interference scenarios;

- Easy Installation and Integration: Supports both horizontal and inclined installation methods to adapt to different production line layouts; a dedicated adapter plate is required for installation (the minimum thickness of the PFTL101B adapter plate is 35mm), and it can be put into use without complex debugging;

- High Compatibility: It can seamlessly connect with ABB PFEA series tension controllers, and is also compatible with various PLC and DCS systems. Supporting standard analog signal output, it can be flexibly integrated into various industrial automation control systems. In addition, it can be used in parallel and is compatible with redundancy technology to improve system reliability.

IV. Application Scenarios

As a medium-range high-precision tension/load measurement device, this sensor is suitable for tension detection of medium-load strip, plate, cable and other materials, as well as pressure monitoring and weight metering of industrial equipment. Relying on its stability and adaptability, it is widely used in the following industries and scenarios:

- Metal Processing Industry: Used for tension control of strips in hot rolling, cold rolling, annealing and galvanizing production lines, as well as tension measurement in metal wire processing lines; it can accurately capture tension fluctuations to ensure uniform material processing and reduce the defective rate;

- Paper Making, Printing and Packaging Industry: Adapted to paper machines, calenders, coaters, winders and other equipment for the transverse tension measurement and control of paper, film and other materials, ensuring the flatness and consistency of products;

- Other Industrial Fields: Including yarn tension control of textile machinery, weight metering of automated production lines, pressure monitoring of material handling equipment, and precise weighing and tension control in food processing, chemical manufacturing, pharmaceutical production and other scenarios. It can also be applied in industrial occasions with heavy rolls, a wide tension range and high operating speed.