Description

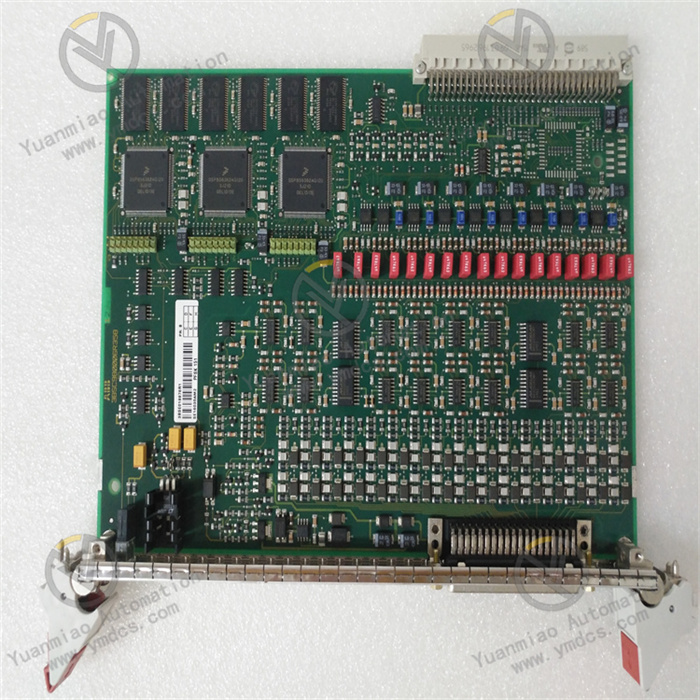

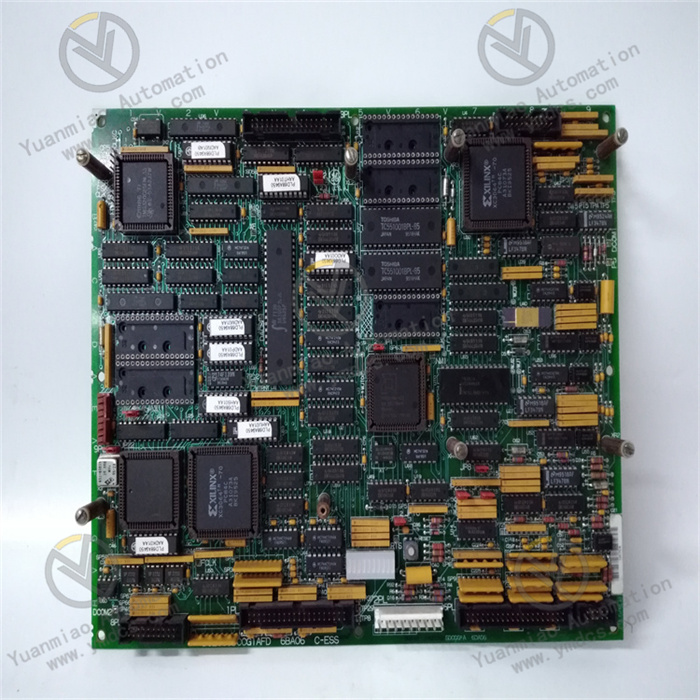

ABB SD832 3BSC610065R1

I. Overview

ABB SD832 3BSC610065R1 is a switching power supply module, with its core positioning as a precision power supply unit for automation control systems. It belongs to the supporting power supply product line of ABB 800xA and Advant OCS systems, and is originally manufactured in Sweden. Tailor-made for mainstream ABB automation equipment such as AC 800M controllers and S800 I/O modules, this module adopts wide-range AC auto-adaptive input, which can be accurately converted into a stable 24V DC output. Equipped with redundancy linkage capability and multiple safety protection features, it can provide reliable DC power for downstream sensors, actuators and control modules. It is widely applicable to scenarios with stringent requirements for power supply stability, such as petrochemical, power control and intelligent manufacturing industries, serving as a core power supply component to ensure the continuous operation of automation systems.

II. Core Features

Wide-voltage Auto-adaptive Input: Supports dual-range AC input of 100-120V AC/200-240V AC with automatic identification and switching function, eliminating the need for manual gear adjustment. It can be directly adapted to grid standards in different regions around the world without additional adapter equipment, greatly improving scenario adaptability.

High-efficiency and Stable Output Performance: Provides a fixed 24V DC output with a rated output current of 5A and a rated output power of 120W. Adopting PWM technology, it boasts excellent energy conversion efficiency and low output ripple noise, which can supply stable power for precision control equipment and avoid equipment faults caused by voltage fluctuations.

Redundancy Linkage and Flexible Expansion: Supports linkage with SD8xx series voting units to build an N+1 redundant power supply system. When the main module fails, the backup module quickly takes over the power supply, significantly improving the reliability of system power supply and meeting the high fault tolerance requirements of key processes.

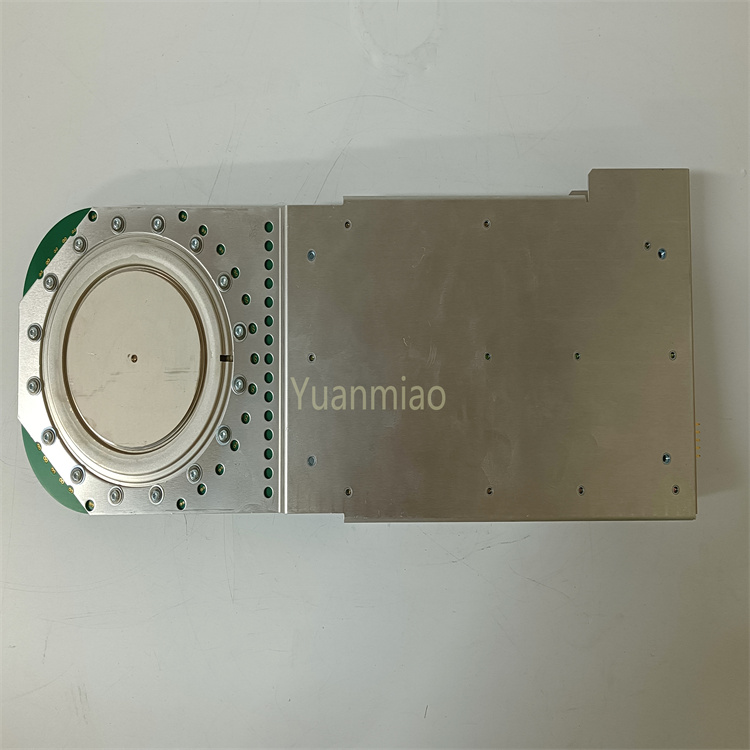

- Compact Design and Convenient Operation & Maintenance: Adopts standardized DIN rail mounting with a compact outline dimension of only 32mm (width) × 124mm (height) × depth (adapted to rail space) and a weight of 0.56kg, occupying little space in control cabinets. The modular design facilitates quick installation, disassembly and replacement, reducing operation and maintenance costs.

III. Technical Parameters

| Parameter Name | Specification |

|---|---|

| Product Model | ABB SD832 3BSC610065R1 |

| Product Type | Industrial-grade Switching Power Supply Module (Static Converter) |

| Country of Origin | Sweden |

| Input Parameters | AC input: 100-120V AC / 200-240V AC (automatic identification and adaptation); Rated input power: 240/283 VA |

| Output Parameters | DC output: 24V DC fixed output, rated current 5A, rated power 120W; Modulation method: PWM |

| Dimensions | 32mm (W) × 124mm (H), overall size suitable for DIN rail mounting; Shipping size: approx. 3.2×12×13cm |

| Product Weight | Net weight 0.56kg |

| Installation Method | DIN rail mounting |

| Environmental Adaptability | Operating temperature: 0℃~60℃; Storage temperature: -20℃~85℃; Suitable for dry and dust-free industrial environments |

| Redundancy Function | Supports linkage with SD8xx series voting units to realize redundant power supply configuration |

| Protection Features | Built-in overcurrent, overvoltage and short-circuit protection, with strong resistance to grid interference |

IV. Working Principle

ABB SD832 3BSC610065R1 power supply module realizes efficient and stable power supply based on the closed-loop working process of wide-voltage auto-adaptation - rectification and filtering - high-frequency PWM conversion - regulated output - redundancy linkage monitoring. The specific working process is divided into five core stages:

After the module is connected to the power grid, its internal voltage detection circuit automatically identifies the input voltage range (100-120V AC or 200-240V AC) without manual gear switching. Meanwhile, the surge protection circuit filters out instantaneous high-voltage interference in the grid, ensuring that the input voltage stably enters the next processing link.

The AC input voltage is converted into DC power by the internal rectifier bridge, and then the clutter, ripple and electromagnetic interference signals are removed by the high-precision filter circuit to purify the voltage waveform. This provides a pure DC power foundation for subsequent high-frequency power conversion and avoids external interference affecting output stability.

Relying on PWM technology, the filtered DC power is converted into high-frequency pulse voltage by adjusting the on and off time (duty cycle) of internal switching tubes, precisely controlling the amplitude of output voltage. Compared with traditional linear power supplies, it greatly improves energy conversion efficiency and reduces energy loss and module heating.

The high-frequency pulse voltage is converted into stable 24V DC power after secondary rectification and filtering, and the output current is dynamically adjusted according to downstream load demands, maintaining a maximum rated output of 5A. At the same time, the output status is monitored in real time. When abnormalities such as overcurrent, overvoltage and short circuit are detected, the protection mechanism is activated immediately to cut off the output or limit the current, ensuring the safety of the module and downstream equipment.