Description

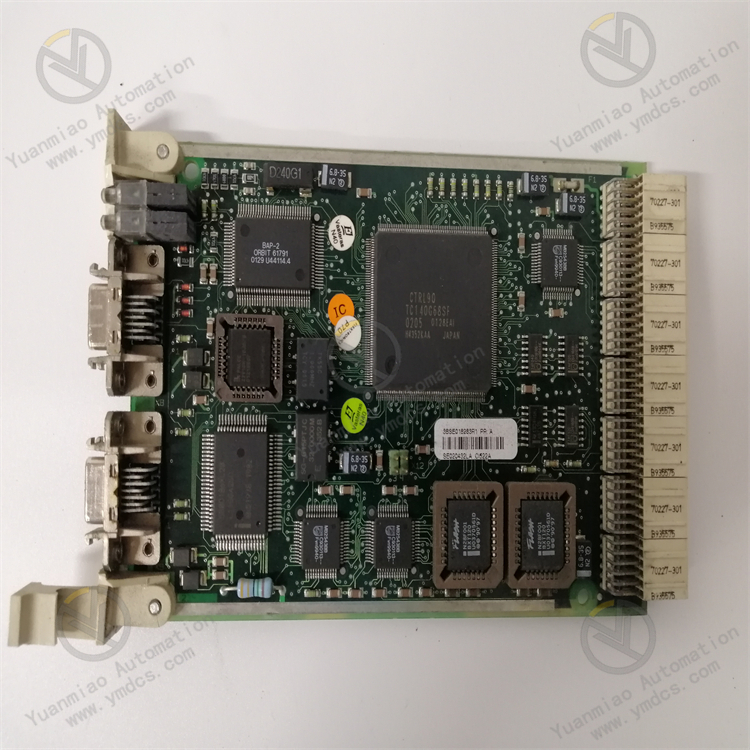

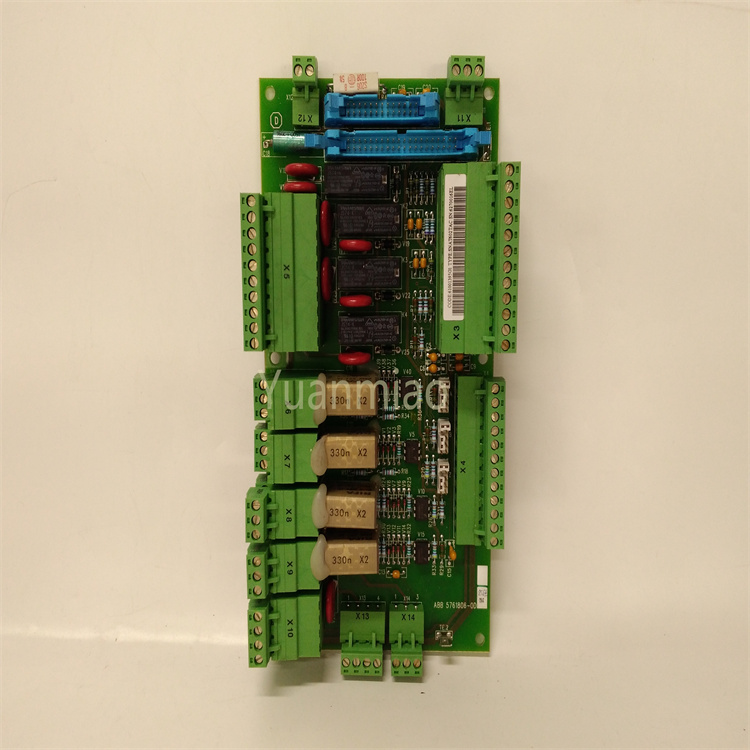

ABB DO801 3BSE020510R1

I. Overview

The ABB DO801 3BSE020510R1 is a digital output module, with its core positioning as a universal digital signal output unit for Distributed Control Systems (DCS). Designed specifically for medium and low-load industrial automation scenarios, this module drives executive components such as relays, contactors, solenoid valves and indicator lights by outputting switching signals, to accurately complete basic control actions including equipment start-stop, valve switching and alarm triggering.

With its stable and reliable relay output design, simple configuration and strong environmental adaptability, it is widely used in fields such as power auxiliary systems, chemical auxiliary control, water treatment, papermaking and general machinery automation. It seamlessly integrates with the ABB AC 800M distributed control system, providing stable signal output support for the automation link, and serves as a basic component with both versatility and practicality in the industrial control system.

II. Product Features

Standard 8-channel Design: The single module integrates 8 independent digital output channels, with each channel designed for independent control and diagnosis. It is suitable for medium and low-load control scenarios, balancing control precision and space utilization. The output type is relay contact output, supporting Normally Open (NO) mode. The contact capacity meets the requirements of most general executive components, enabling direct driving of small loads without additional intermediate relays, thus simplifying system wiring.

Stable and Reliable Output Protection: It adopts industrial-grade sealed relays with contacts featuring excellent arc resistance and wear resistance, extending service life. Each channel is equipped with built-in overload protection and contact status monitoring functions, which can automatically identify abnormal working conditions such as load overload and contact adhesion, preventing fault spread. It supports optional redundant power supply, effectively avoiding control interruption caused by single power supply failure and ensuring link continuity.

Convenient Configuration and Rapid Integration: It is fully compatible with the ABB AC 800M controller. Channel parameter configuration, fault threshold setting and linkage logic programming can be completed via the Control Builder configuration software, featuring an intuitive interface and simple operation. It adopts the S800 I/O standard bus interface and DIN rail mounting design, supporting hot-swapping function. Module replacement and maintenance can be performed without shutdown, minimizing production interruption time.

Strong Anti-interference and Environmental Adaptability: It has excellent Electromagnetic Compatibility (EMC), passing rigorous industrial electromagnetic interference tests. With signal isolation and shielding design, it can effectively resist strong electromagnetic radiation, voltage fluctuations and other interferences in industrial sites, ensuring signal output stability. It has an IP20 protection rating, adapting to industrial environments with dust, humidity and alternating high and low temperatures. The operating temperature range covers -25℃ ~ +60℃, meeting the requirements of various general industrial working conditions.

Comprehensive Fault Diagnosis and Status Feedback: It has a built-in complete self-diagnosis function, real-time monitoring the relay contact status and load connection of each channel. Upon detecting faults (contact adhesion, overload, open circuit), it immediately generates a fault code and feeds it back to the upper controller, while intuitively indicating the fault location through the module indicator light. It supports real-time channel status readback, facilitating remote monitoring and rapid fault troubleshooting by operators, and improving operation and maintenance efficiency.

- High Versatility and Standard Compatibility: It complies with the IEC 61131-2 industrial standard, being compatible with the installation rails, communication protocols and configuration logic of ABB S800 I/O series modules. It can be flexibly combined with AI and DI modules of the same series to adapt to the expansion needs of different control scenarios. The relay output conforms to industrial general standards, being compatible with mainstream brand medium and low-load executive components on the market and featuring strong versatility.

III. Technical Parameters

1. Core Basic Parameters

- Product Model: ABB DO801 3BSE020510R1

- Product Type: Industrial-grade Digital Output Module (DO Module, relay output)

- Brand Series: S800 I/O Series Supporting ABB AC 800M Controller

- Core Functions: 8-channel digital signal output, relay contact driving, fault self-diagnosis, overload protection, hot-swapping

- Compatible System: ABB AC 800M Distributed Control System

- Compatible Actuators: Relays, contactors, solenoid valves, indicator lights, small electromagnetic actuators, etc.

- Application Fields: Power auxiliary systems, petrochemical auxiliary control, metallurgical auxiliary machinery, water treatment, papermaking and printing, general machinery automation, rail transit auxiliary control, etc.

2. Electrical Performance Parameters

- Supply Voltage: 24 VDC (allowable fluctuation range: 19.2V DC ~ 28.8V DC), supporting redundant power supply (optional)

- Number of Output Channels: 8 independent digital output channels, with independent contact design

- Output Type: Relay output (changeover contact, Normally Open priority)

- Contact Capacity: Max. 250V AC/2A, 30V DC/2A (resistive load); 250V AC/1A, 30V DC/1A (inductive load)

- Response Time: ≤ 10ms (contact closing time), ≤ 10ms (contact opening time)

- Communication Interface: Communicates with AC 800M controller via S800 I/O bus

- Isolation Method: Electrical isolation between channels, photoelectric isolation between module and bus (isolation voltage ≥ 2500V AC, lasting for 1 minute)

- Protection Functions: Overload protection, contact adhesion detection, and reverse connection protection for each channel

3. Environmental and Physical Parameters

- Operating Temperature: -25℃ ~ +60℃

- Storage Temperature: -40℃ ~ +85℃

- Relative Humidity: 5% ~ 95% RH (non-condensing)

- Protection Rating: IP20 (panel-mounted, compliant with IEC 60529 standard)

- Dimensions: 100mm (length) × 160mm (width) × 80mm (height) (compatible with S800 I/O standard guide rails)

- Weight: Approximately 0.4 kg

- Mounting Method: 35mm DIN rail mounting (compliant with EN 60715 standard), supporting hot-swapping

- Vibration Resistance: Frequency 10-500Hz, acceleration 2g (sine wave), compliant with IEC 60068-2-6 standard

- Shock Resistance: Acceleration 15g, duration 11ms, compliant with IEC 60068-2-27 standard

IV. Working Principle

The core working principle of the ABB DO801 3BSE020510R1 digital output module is a closed-loop control process of upper-level command receiving - signal decoding and driving - relay action - status feedback and diagnosis. Through the coordinated operation of the bus communication module, relay driving module, protection module and diagnosis module, it achieves precise linkage between the controller and on-site medium and low-load actuators. The specific working process can be divided into four core stages:

Stage 1: Command Receiving StageThe module establishes stable two-way communication with the ABB AC 800M controller via the S800 I/O bus, and real-time receives digital control commands (high-level/low-level signals) issued by the upper controller. The communication module verifies and decodes the received command signals, filters out electromagnetic interference clutter during bus transmission, ensures the integrity and accuracy of the commands, and simultaneously feeds back the module's own working status (power supply, bus connection) to the upper controller in real time.

Stage 2: Signal Driving StageThe decoded control commands are transmitted to the relay driving module, which controls the on-off of the relay coil of the corresponding channel according to the command signals: when receiving the "turn-on" command, the coil is energized to generate magnetic force to close the contacts and output switching signals; when receiving the "turn-off" command, the coil is de-energized, and the contacts reset under the action of the spring to cut off the output signals, achieving precise control of the actuators.

Stage 3: Actuator Driving StageAfter the relay contacts act, the switching signals are transmitted to on-site actuators (such as solenoid valves, indicator lights) through the module terminals, driving the actuators to complete preset control actions. During the driving process, the protection module real-time monitors the load current and contact status of each channel. If abnormalities such as overload or contact adhesion are detected, it immediately cuts off the driving signal of the corresponding channel to prevent actuator damage and fault spread.

V. Common Fault Troubleshooting

1. No Output Signal from the Module and No Action of Actuators

- Detect the module supply voltage to ensure stable 24VDC power supply with a fluctuation range of 19.2V ~ 28.8V. If optional redundant power supply is configured, check the connection of the backup power supply, switch to the backup power supply and troubleshoot the faulty power supply.

- Check the bus line connectors, re-tighten them and test continuity; verify the module address and communication protocol through the configuration software to ensure unique and consistent parameters, and restart the module and controller to restore communication.

- Verify the correctness of the terminal wiring, correct the reverse connection of positive and negative poles, clean the oxide layer of the terminals and re-plug them, and repair the open-circuit lines.

- Disconnect the connection between the module and the actuator, test the continuity and insulation of the actuator separately, and replace the faulty actuator in a timely manner.

- Switch to an idle channel or replace the backup module for testing. If the backup channel/module works normally, it is determined that the relay of the original channel is damaged. Contact ABB official after-sales service for maintenance or module replacement.

2. Relay Contact Adhesion, Unable to Cut Off Output

- Immediately cut off the power supply of the corresponding channel of the module to stop the load operation and avoid fault expansion. Verify the rated current of the actuator to ensure it does not exceed the contact capacity (2A/250V AC for resistive load, 1A/250V AC for inductive load). If the load is too large, install an intermediate relay.

- Replace the module corresponding to the faulty channel or replace the entire module to avoid secondary faults caused by using damaged contacts.

- Optimize the control logic to reduce unnecessary frequent start-stop, extending the service life of the relay; improve the module installation environment, reduce temperature and humidity, and avoid contact oxidation.

- Check the overload protection parameter configuration of the module to ensure the parameters match the load characteristics and trigger the protection mechanism in a timely manner.

3. Communication Interruption Between the Module and the Controller

- Disconnect the power supply to check the bus line, re-tighten the connectors and test continuity, and repair the damaged line; avoid parallel routing of the bus and power lines to reduce strong electric crosstalk.

- Replace the shielded bus cable, reliably ground the shield layer at one end (grounding resistance ≤ 4Ω), and keep away from strong interference sources such as high-power equipment.

- Modify the module address through the configuration software to ensure a unique address, and restart the module and controller to take effect.

- Replace the backup module and connect it to the bus. If the backup module communicates normally, it is determined that the communication interface of the original module is damaged. Contact ABB after-sales service for maintenance.

- If multiple modules cannot communicate, troubleshoot the controller bus interface fault, repair or replace the controller bus module.

4. The Module Fails to Be Recognized by the Controller After Hot-swapping

- Re-plug the module according to the standard process: first cut off the module power supply, pull out the module, clean the oxide layer of the pins and guide rail contacts, reinsert it to ensure reliable contact, and then restore the power supply.

- Check the bus connector, re-tighten it and confirm no damage, and repair the displaced or damaged connector.

- Refresh the controller module configuration information through the configuration software, restart the controller and the module to ensure the controller recognizes the module and loads the configuration parameters.

- If the operation is ineffective after multiple attempts, replace the backup module for testing to troubleshoot the problem of damaged hot-swapping contacts of the original module.