Description

ABB DC551-CS31 1SAP220500R0001

I. Overview

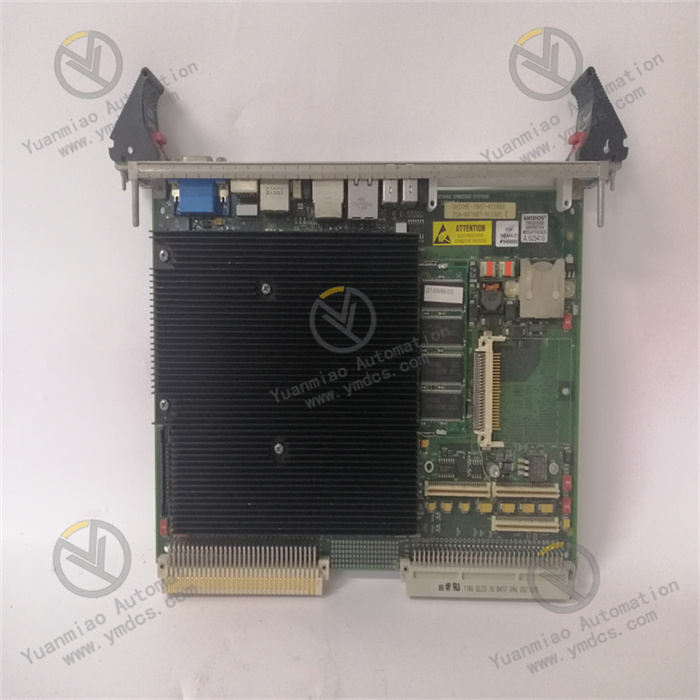

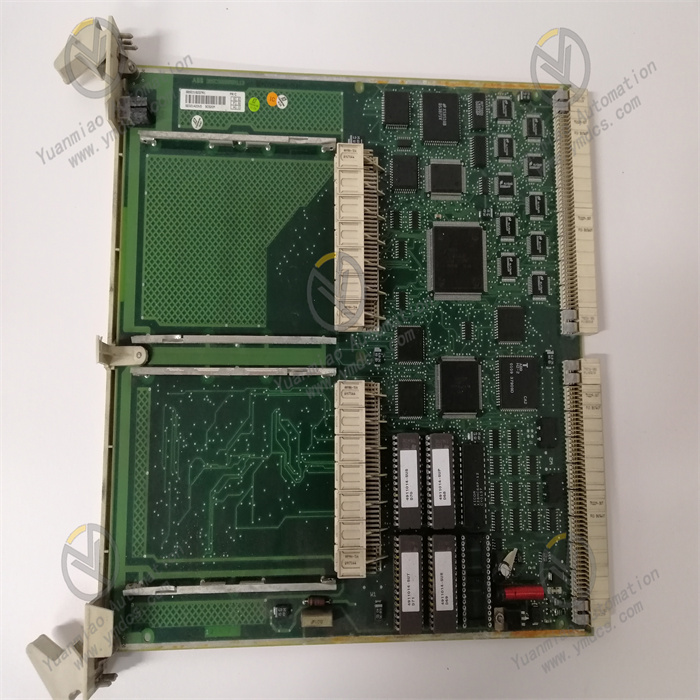

ABB DC551-CS31 (Order Number: 1SAP220500R0001) is a communication gateway module originally manufactured in Sweden. Its core function is to achieve seamless conversion and data bridging between different industrial Ethernet protocols. Acting as a "translator" for the interconnection of cross-brand and cross-system devices, it breaks information silos in industrial control systems and ensures efficient and reliable data interaction.

Widely deployed between the control layer and device layer, this product is suitable for various industrial scenarios such as automotive manufacturing, food and beverage, and energy management. It can connect various industrial devices including PLCs, HMIs, frequency converters, and robot controllers to construct a unified and open industrial communication network, serving as a key component for realizing "transparent factories" and "digital twins". It has advantages such as multi-protocol compatibility, redundant communication, and wide temperature adaptability, and is compatible with mainstream PLC platforms including Siemens S7 series, Rockwell ControlLogix, and ABB AC800 series.

II. Product Features

Seamless Multi-protocol Compatibility: Natively supports three mainstream industrial Ethernet protocols, namely PROFINET, Modbus TCP, and EtherNet/IP. It can be flexibly configured as a protocol converter, data gateway, or redundant communication node, enabling easy cross-system integration of devices with different brands and protocols.

Redundant Ring Network Protection: Equipped with 2 RJ45 Ethernet ports, supporting 10/100 Mbps adaptive transmission. It can be used to build a redundant ring network with a network fault recovery time of less than 500ms, which greatly improves the continuity and availability of the communication system and is suitable for critical industrial scenarios with high requirements for communication reliability.

Wide Temperature Range Adaptability: The operating temperature range covers -20℃ to +60℃, and the storage temperature range reaches -40℃ to +85℃. It can withstand harsh industrial environments such as high and low temperatures and electromagnetic interference. With an IP20 protection rating for the module itself, it is suitable for installation and deployment in industrial control cabinets.

Broad Platform Compatibility: Fully compatible with mainstream PLC platforms including Siemens S7 series, Rockwell ControlLogix, and ABB AC800 series. Meanwhile, it can connect to various industrial devices such as frequency converters, robot controllers, and HMIs, featuring high deployment flexibility.

International Standard Certification: Certified by multiple international authoritative organizations including CE, UL, CCC, and ATEX Zone 2. It complies with safety and performance standards in the global industrial field and can be safely applied in key industries such as petrochemicals, energy, and automotive manufacturing.

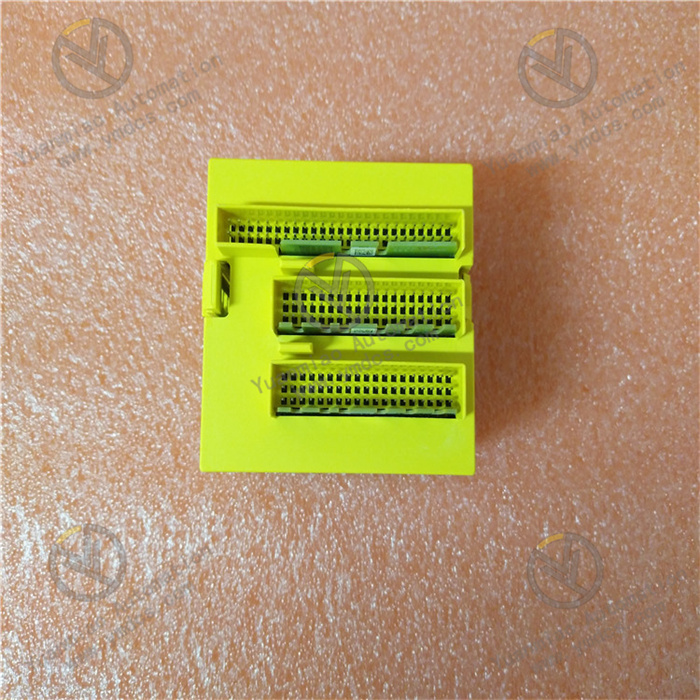

- Compact and Convenient Installation: Adopts a standard DIN rail mounting design with dimensions of only 45mm × 125mm × 110mm and a weight of approximately 0.2kg. Its compact structure effectively saves space in control cabinets and facilitates batch deployment and later maintenance.

III. Technical Parameters

1. Core Basic Parameters

- Product Model: DC551-CS31

- Order Number: 1SAP220500R0001

- Product Type: Industrial Automation Communication Gateway Module

- Manufacturer: ABB

- Place of Origin: Sweden

2. Communication Performance Parameters

- Supported Protocols: PROFINET, Modbus TCP, EtherNet/IP

- Network Interfaces: 2×RJ45 Ethernet Ports

- Transmission Rate: 10/100 Mbps (Adaptive)

- Network Functions: Supports redundant ring network with recovery time < 500ms

3. Power Supply and Environmental Parameters

- Supply Voltage: 24V DC (±20%)

- Power Consumption: Approximately 5W

- Operating Temperature: -20℃ to +60℃

- Storage Temperature: -40℃ to +85℃

- Protection Rating: IP20 (Module itself)

4. Physical and Certification Parameters

- Dimensions: 45mm × 125mm × 110mm

- Weight: Approximately 0.2kg

- Mounting Method: Standard DIN Rail Mounting

IV. Working Principle

The core working principle of the ABB DC551-CS31 1SAP220500R0001 communication gateway is "Protocol Parsing - Data Conversion - Transparent Transmission". Through the built-in multi-protocol processing unit, it realizes bidirectional data interaction between different industrial Ethernet protocols and constructs a unified communication link between the control layer and the device layer.

The specific working process is divided into three core stages: First, in the signal collection stage, the gateway connects to device networks with different protocols through two RJ45 Ethernet ports respectively (e.g., Siemens PLC in the PROFINET network and Rockwell frequency converter in the EtherNet/IP network), and collects real-time operation data (such as motor speed, load current, fault status) and control commands from each device. Second, in the protocol conversion stage, the built-in processing unit parses the collected data of different protocols, extracts the core data content, and then repackages it according to the format specifications of the target protocol to complete the "translation" conversion between protocols, ensuring the accuracy of data semantics. Finally, in the data transmission stage, the converted standardized data is transmitted to the target device or upper-level control system through the redundant ring network link. Meanwhile, the gateway monitors the network status in real time. If the primary link fails, it can automatically switch to the backup link within 500ms to ensure uninterrupted data transmission.

In addition, through precise time sequence synchronization and data caching mechanisms, the gateway ensures the real-time performance and integrity of cross-protocol data transmission, with the transmission delay controlled at the millisecond level, meeting the stringent requirements of industrial sites for real-time control. Its IP20 protection design and wide temperature adaptability ensure stable operation in the complex environment inside industrial control cabinets, providing reliable support for device interconnection and data-driven decision-making in smart factories.

V. Common Troubleshooting

1. Communication Interruption/Failure to Establish Connection

Phenomenon: The gateway fails to establish communication with upstream and downstream devices/control systems. The upper-level system displays no data, or prompts "communication timeout" or "device offline".

Causes: Damaged Ethernet cable, poor contact or loose crimping of the crystal head; incorrect IP address configuration (e.g., conflict with other devices in the network, mismatched subnet mask); abnormal configuration of the redundant ring network, resulting in an unclosed link; unstable power supply voltage of the gateway or power outage.

Solutions: 1. Inspect the appearance of the Ethernet cable, test its continuity with a cable tester, replace the damaged cable or re-crimp the crystal head to ensure the connector is fully inserted with a "click" locking sound. 2. Log in to the gateway configuration interface, check the IP address, subnet mask, and gateway address to ensure they match the network segment of the host network without address conflicts. 3. Inspect the wiring of the redundant ring network, confirm that all nodes are correctly connected to the ring network, reconfigure the ring network parameters and restart the gateway. 4. Measure the power supply voltage of the gateway to ensure it is 24V DC (±20%), and check the power supply line connectors to eliminate loosening or power outage issues.

2. Data Transmission Delay/Packet Loss

Phenomenon: The data displayed on the upper-level system is updated with a lag, inconsistent with the actual operating status of the device; packet loss occurs during data transmission, leading to delayed execution of control commands or incorrect fault judgment.

Causes: Excessively high network bandwidth utilization with a large number of broadcast storms or invalid data; the communication distance between the gateway and the device exceeds the transmission limit of the Ethernet cable (the recommended distance for Cat 5e cable is no more than 100 meters); improper configuration of protocol conversion parameters with an overly small data cache setting; strong electromagnetic interference near the gateway.

Solutions: 1. Troubleshoot abnormal devices in the network to reduce broadcast data, and divide VLANs to isolate different device network segments if necessary. 2. If the communication distance is too long, install an industrial Ethernet switch for signal relay or switch to a fiber optic transmission solution. 3. Log in to the gateway configuration interface to optimize protocol conversion parameters and appropriately increase the data cache capacity. 4. Check the installation location of the gateway, keep it away from strong electromagnetic interference sources such as frequency converters and high-power motors, add shielding layers to the cables and ensure single-point grounding.

3. Gateway Failure to Start/Frequent Restarts

Phenomenon: The gateway has no indicator light on after being powered on and fails to start; or it automatically restarts frequently after startup and cannot run stably.

Causes: The power supply voltage is beyond the allowable range (<19.2V DC or >28.8V DC); power module failure with unstable output voltage; damaged internal circuit of the gateway; the operating environment temperature exceeds the working range of -20℃ to +60℃, triggering overheat protection.

Solutions: 1. Inspect the power supply, replace it with a well-performing 24V DC power module to ensure the output voltage is stably maintained between 19.2V DC and 28.8V DC. 2. Check the appearance of the gateway for bulges or ablation marks. If there are signs of internal circuit damage, contact ABB official after-sales service for repair or replacement. 3. Check the temperature inside the control cabinet. If it exceeds the working temperature range, install cooling fans or air conditioners to improve ventilation and heat dissipation conditions.

4. Abnormal Protocol Conversion/Incorrect Data Parsing

Phenomenon: The data displayed on the upper-level system is incorrect, garbled, or inconsistent with the actual parameters of the device; control commands cannot be correctly identified and executed by the target device.

Causes: Incorrect configuration of protocol conversion parameters (e.g., mismatched data byte order, register address mapping, or data type); failure to select the correct target protocol type; outdated gateway firmware version with protocol parsing vulnerabilities; mismatched communication parameters (such as baud rate and parity check) between upstream and downstream devices and the gateway.

Solutions: 1. Refer to the device manual to recheck and correct the protocol conversion parameters of the gateway, ensuring the accuracy of register address, data type, byte order and other configurations. 2. Confirm that the correct target protocol type is selected to match the protocol types of upstream and downstream devices. 3. Log in to the official ABB website to download and upgrade the gateway to the latest firmware version to fix parsing vulnerabilities. 4. Verify the communication parameters of upstream and downstream devices to ensure they are consistent with the gateway configuration.

![]()