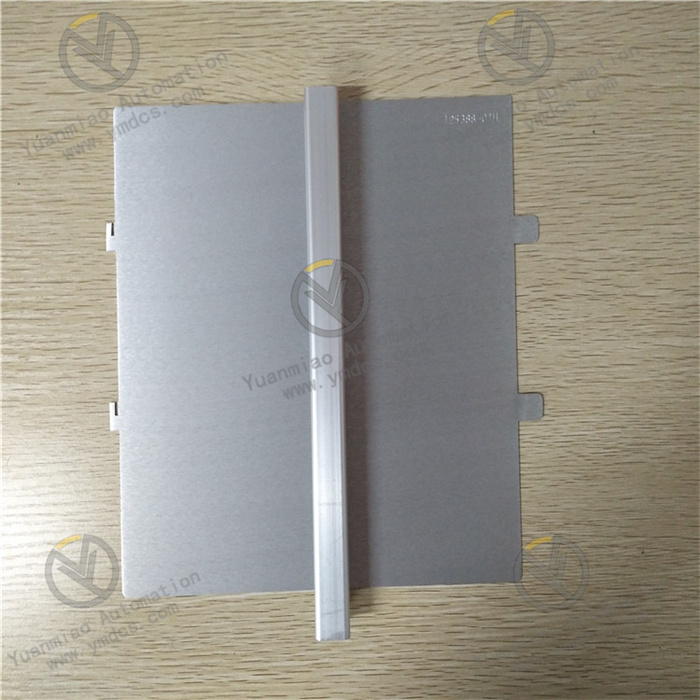

Description

ABB AI845 3BSE023675R1

ABB AI845 3BSE023675R1 is an analog input module designed for industrial automation control systems (e.g., ABB 800xA System). As a critical signal acquisition component, it enables precise collection, conditioning, and conversion of analog signals output by various sensors for temperature, pressure, flow rate, etc., transforming them into digital signals recognizable by controllers. This module provides reliable data support for process control, data acquisition, and test & measurement scenarios.

Equipped with 8 input channels, it supports multiple standard analog signal types, integrates HART protocol communication functionality and advanced onboard diagnostics. Featuring an industrial-grade high-reliability design, it is widely applied in automation control systems across manufacturing, energy, and infrastructure sectors. It seamlessly integrates with ABB series controllers and dedicated terminal units, ensuring stable and efficient system operation.

The AI845 3BSE023675R1 module effectively enhances system anti-interference capability and safety through its current-limited transmitter power supply design and input-output isolation technology. Its flexible configuration options and modular architecture not only facilitate system expansion and maintenance but also adapt to the personalized requirements of different industrial scenarios, making it an ideal choice for high-precision signal acquisition in industrial automation.

It is configured with 8 single-ended analog input channels, supporting multiple standard input types such as 0(4)-20mA current signals and 0(1)-5V voltage signals, to meet the signal acquisition needs of diverse sensors. Adopting a 12-bit resolution signal conversion circuit with a measurement accuracy of 0.1%, it can accurately capture weak signal variations, providing high-quality raw data support for control systems.

It natively supports HART protocol communication, enabling two-way data exchange with HART-enabled intelligent sensors. Beyond collecting measured signals from sensors, it can also retrieve sensor operating status, configuration parameters, and other information. Meanwhile, it allows remote configuration and calibration of sensors via the HART protocol, enhancing the intelligent operation and maintenance level of the system.

The module employs an isolation design between input and output channels, with a rated isolation voltage of 50V, effectively preventing external signal interference from affecting the module and backend control systems. It also incorporates a current-limited transmitter power supply function, which provides stable power for front-end sensors while preventing equipment damage due to overcurrent, thus improving the safety and reliability of system operation.

Built-in advanced onboard diagnostic functions enable real-time monitoring of the module's operating status, input signal integrity, and power supply conditions. Upon detecting issues such as signal anomalies, channel faults, or unstable power supply, it promptly generates fault information and feeds it back to the control system, allowing maintenance personnel to quickly locate fault causes and reduce system downtime.

As a standard module of the ABB S800 I/O Series, it features a modular design and supports DIN rail mounting, enabling flexible integration into standard distribution cabinets. It is compatible with mainstream control systems like ABB 800xA and requires matching with dedicated terminal units (e.g., TU 810, TU 812, TU 814, etc.). Additionally, it supports connection with third-party control systems, facilitating system expansion and upgrading.

- Model: ABB AI845 3BSE023675R1

- Product Type: Analog Input Module

- Product Series: ABB S800 I/O Series

- Brand: ABB

- Application Fields: Manufacturing, Energy Industry (Power, Oil, Natural Gas), Infrastructure (Construction, Transportation, Water Conservancy)

- Compatible Systems: Industrial automation control systems such as ABB 800xA

- Compatible Terminal Units: TU 810, TU 812, TU 814, TU 818, TU 830, etc.

- Mounting Method: DIN Rail Mounting

- Net Weight: 0.34kg

- Warranty Period: 12 Months

- RoHS Compliance: Conforms to EU Directive 2011/65/EU

- Number of Input Channels: 8 Channels (Single-ended)

- Input Signal Types: Current Signals (0-20mA, 4-20mA), Voltage Signals (0-5V, 1-5V)

- Resolution: 12-bit

- Measurement Accuracy: ±0.1% FS

- Isolation Class: Input-output isolation, rated isolation voltage 50V

- Power Supply Mode: Current-limited transmitter power supply

- Communication Interface: HART Protocol Supported

- Communication Protocol: HART, compatible with industrial standard communication protocols

- Power Consumption: Refer to system manual (Typical low-power design)

- Dimensions (W×H×D): 45mm×119mm×102mm

- Operating Temperature: -25℃~+70℃ (Typical value, subject to physical product specifications)

- Storage Temperature: -40℃~+85℃

- Relative Humidity: 5%~95%RH (Non-condensing)

- Electromagnetic Immunity: Complies with EN 55011, EN 61000 series standards

- Vibration Resistance: Complies with IEC 60068-2-6 standard

- Shock Resistance: Complies with IEC 60068-2-27 standard

- WEEE Category: Category 5 (Small equipment with external dimensions not exceeding 50cm in all aspects)

The core working logic of the ABB AI845 3BSE023675R1 Analog Input Module follows the sequence of "Signal Access - Conditioning & Preprocessing - Conversion & Transmission - Status Monitoring - Diagnostic Feedback". The detailed workflow is as follows:

Signal Access and Power Supply: Analog signals output by front-end sensors (e.g., temperature, pressure sensors) are connected to the module’s 8 input channels via dedicated terminals. The module supplies stable power to sensors through its current-limited transmitter power supply circuit while restricting output current to prevent sensor damage from overloading.

Signal Conditioning and Preprocessing: The incoming analog signals first undergo noise reduction and signal enhancement via the module’s internal filtering and amplification circuits, eliminating electromagnetic interference signals present in industrial environments. Electrical isolation between input signals and backend circuits is achieved through isolation circuits, improving signal stability and system safety.

A/D Conversion and Data Transmission: Preprocessed analog signals are converted into digital signals by a 12-bit A/D conversion circuit. After processing by the internal logic circuit, the digital signals are transmitted to the ABB controller (e.g., 800xA System Controller) via the system bus. For HART intelligent sensors, the module enables two-way transmission of measured data and sensor status information through the HART protocol, supporting remote configuration and calibration.

Status Monitoring and Diagnostic Feedback: The module continuously monitors its power supply status, input channel signal integrity, and A/D conversion circuit operation. Upon detecting anomalies, it activates the onboard diagnostic mechanism, generates fault codes, and transmits them to the control system via the communication link, while triggering corresponding alarm indicators to facilitate rapid troubleshooting by maintenance personnel.

![]()