Description

ABB CP6615 1SAP561510R0001

I. Product Overview

ABB CP6615 1SAP561510R0001 is a Human - Machine Interface (HMI), positioned as an intelligent interaction hub between operators and industrial control systems. It undertakes key tasks such as complex process visualization monitoring, multi - device collaborative control operation, refined parameter configuration management, and full - link fault diagnosis and feedback. Relying on ABB's advanced industrial electronic design and software configuration technology, this product integrates a high - definition display interface, high - speed communication links, and powerful data processing capabilities. It can achieve seamless connection with ABB's full range of PLCs, frequency converters, DCS systems, and other mainstream brand industrial control equipment, providing convenient and reliable human - machine interaction support for the efficient management and control of large - scale, high - precision industrial production processes.

II. Functional Features

1. High - Definition Visual Interaction with Excellent Operating Experience

2. Multi - Protocol and Multi - Interface Compatibility for High - Speed and Stable Data Interaction

3. Industrial - Grade Strong Protection with Excellent Environmental Adaptability

4. Flexible Configuration Customization for Adapting to Diverse and Complex Scenarios

5. Full - Link Fault Diagnosis for Efficient and Convenient Operation and Maintenance

6. Multiple Safety Protections for Safe and Reliable Operation

7. Redundant Backup Design to Ensure Operation Continuity

III. Technical Parameters

| Category | Specific Parameters |

|---|---|

| Product Model/Part Number | Model: CP6615; Part Number: 1SAP561510R0001 |

| Manufacturer | ABB |

| Product Type | Industrial - Grade High - end Human - Machine Interface (HMI) |

| Display Parameters | Display Screen: 15 - inch TFT LCD screen; Resolution: 1024×768 (high resolution); Display Mode: Graphical display (supporting multi - window, trend chart, report, alarm information, etc.); Backlight Life: ≥50,000 hours (typical value) |

| Touch Parameters | Touch Type: Industrial - grade capacitive touch screen; Support multi - point touch; Touch Response Time: ≤5ms; Operating Temperature: - 20℃~+60℃ |

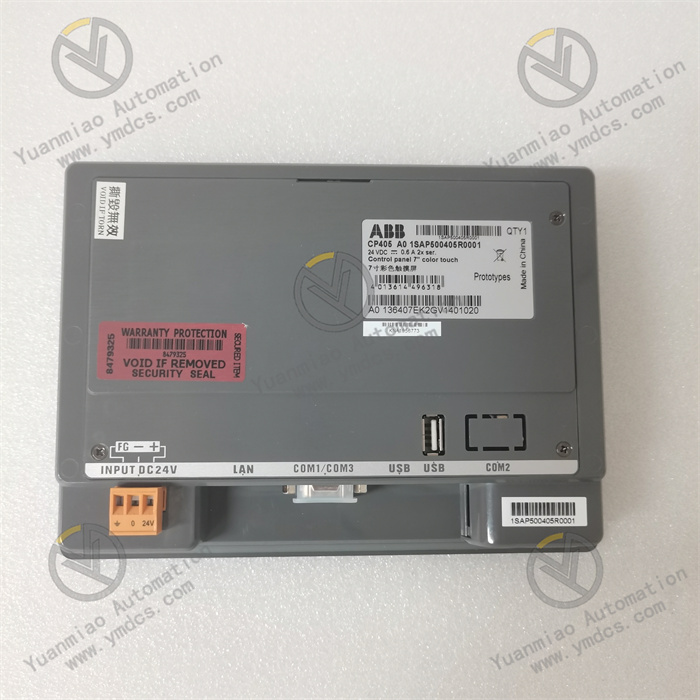

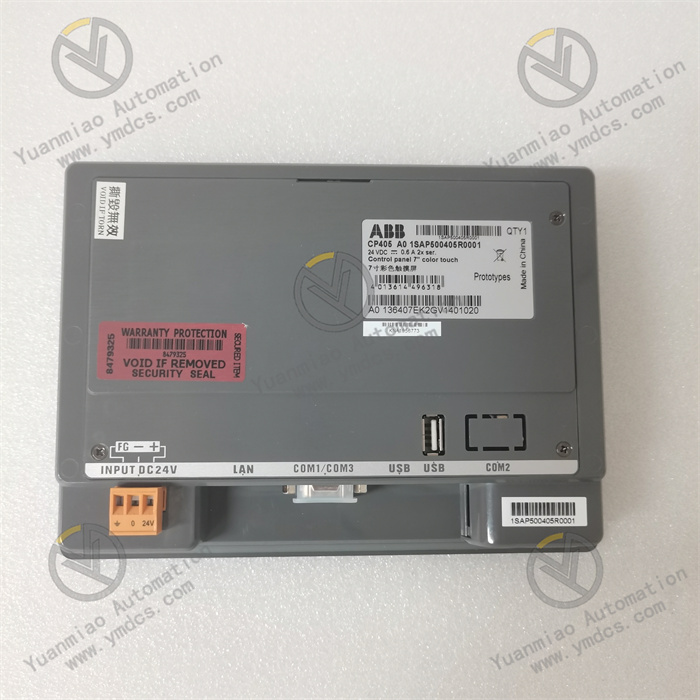

| Communication Parameters | Communication Interfaces: 2×Ethernet interfaces (RJ45, 10/100/1000Mbps), 2×RS485 serial communication interfaces, 2×USB 2.0 interfaces (Type A); Supported Protocols: Modbus TCP, PROFINET, EtherNet/IP, OPC UA, Modbus RTU, etc. |

| Power Parameters | Supply Voltage: 24VDC (rated value); Adaptable Voltage Range: 24VDC±20%; Operating Current: ≤300mA (under rated load); Power Consumption: ≤7.2W (under rated load); Power Protection: Overvoltage, overcurrent, short - circuit and reverse connection protection |

| Protection and EMC | Protection Level: IP65/NEMA 4X (for indoor use); EMC Standards: Compliant with EN 55022 Class A and EN 55011 Class A standards, meeting the requirements of EMC Directive 2014/30/EU; Transient Suppression Performance: ±2kV ESD contact discharge, ±8kV ESD air discharge |

| Environmental Adaptability | Operating Temperature: - 20℃~+60℃; Storage Temperature: - 40℃~+85℃; Relative Humidity: 5%~95% (no condensation); Applicable Environment: Industrial environment with pollution degree 2; Vibration Resistance: 10~500Hz, 1g peak acceleration; Shock Resistance: 50g peak acceleration (11ms duration) |

| Physical Parameters | Installation Method: Panel embedded installation; Overall Dimensions: 354mm×266mm×55mm (length×width×thickness, subject to the actual product); Cutout Dimensions: 330mm×242mm (length×width, subject to the actual product); Net Weight: Approximately 2.5kg (subject to the actual product) |

| Compatible Software and Equipment | Configuration Software: Control Builder Plus, CP600Soft Pro; Compatible Equipment: ABB AC500/AC800 series PLCs, ACS series frequency converters, 800xA DCS systems, and other mainstream brand industrial controllers |

| Application Scenarios | Mid - to high - end industrial automation fields such as intelligent manufacturing production line management and control, chemical refining process control, energy and power monitoring system, rail transit signal control, water treatment process management and control, mining and metallurgy automation, and pharmaceutical industry batch control |

IV. Working Principle

The core working logic of ABB CP6615 1SAP561510R0001 HMI is "Configuration Initialization → Communication Connection Establishment → Two - way Data Interaction → Operation Response and Logic Verification → Status Feedback and Fault Alarm". Through cooperation with industrial control systems and on - site equipment, it completes the full - process and high - precision human - machine interaction tasks. The specific working process is as follows:

Configuration Initialization: Complete personalized interface and function configuration through ABB's dedicated high - end configuration software (such as Control Builder Plus, CP600Soft Pro), including adding multiple types of interactive elements such as process variable display windows, control buttons, multi - level alarm logic, trend chart and report generation templates, and configuring communication parameters (protocol type, IP address, baud rate, etc.), data processing rules, and authority management parameters. After configuration, download the application program to the non - volatile memory (such as Flash) of the HMI device. The device automatically loads the configuration program after power - on, completes hardware self - test and parameter initialization, and enters the ready operation state.

Communication Connection Establishment: The device establishes a stable two - way communication link with control equipment such as PLCs, frequency converters, and DCS through communication interfaces such as Ethernet and RS485. Based on the preset communication protocol, it completes identity authentication, parameter negotiation, and data transmission format adaptation, forming a full - link data transmission channel of "HMI - Controller - On - site Equipment" to ensure the high - speed and accurate transmission of control commands and on - site data.

Two - way Data Interaction: The HMI receives on - site data uploaded by the controller in real time, including various process variables (temperature, pressure, etc.), multi - device operating status, historical process parameter data, and fault alarm information, and visually presents them in a graphical and digital way through the high - definition display screen. At the same time, it receives touch operation instructions from operators in real time (such as equipment start - stop, parameter adjustment, report query, fault reset, etc.), converts the instructions into signal formats recognizable by the controller, and issues them accurately.

Operation Response and Logic Verification: The HMI responds to the touch operations of operators in real time. First, it verifies the operation authority (based on the preset multi - level authority management rules), pops up prompts and intercepts unauthorized operations. It performs logical verification on authorized operation instructions to verify whether the instructions comply with equipment operation specifications and whether process parameters are within the safe threshold range, avoiding production risks caused by misoperation. After passing the verification, it issues the instructions to the controller and displays the operation status synchronously.

- Status Feedback and Fault Alarm: The HMI monitors its own operating status (power supply, display screen, touch panel, communication interface) and the operating status of connected equipment in real time, and identifies problems such as communication interruption, parameter over - threshold, equipment failure, and its own hardware abnormality through the built - in diagnostic algorithm. When an abnormality is detected, it immediately triggers a multi - level alarm mechanism, provides real - time feedback through pop - up alarm prompts on the display screen, highlighting abnormal parameters, and blinking status indicator lights. At the same time, it automatically records fault logs (including fault type, occurrence time, relevant parameters, and fault level), supports local query and upload to the upper - level system, provides accurate basis for operation and maintenance personnel to quickly locate and handle faults, and ensures the stable operation of the system.