Description

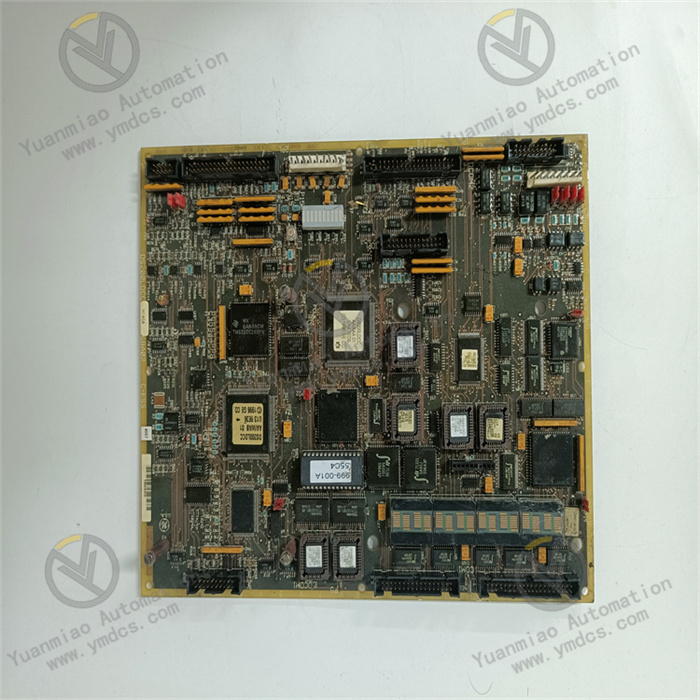

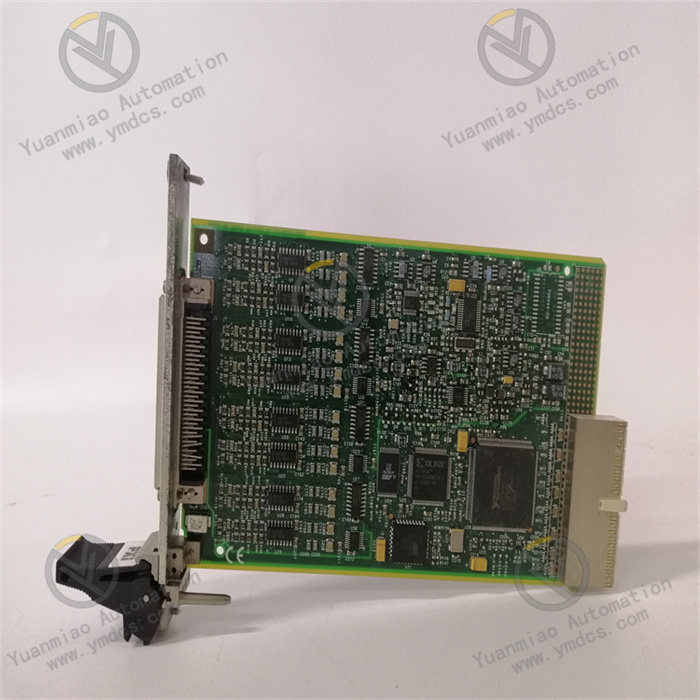

ABB AI835A 3BSE051306R1

I. Product Overview

II. Functional Features

Multi-channel High-precision Signal Acquisition

Each channel supports independent parameter configuration (signal type, measuring range, filter coefficient) and can be custom-calibrated via software, adapting to the output characteristics of different sensors to achieve personalized signal acquisition solutions.

Strong Anti-interference Design and Industrial-grade Reliability

Using industrial-grade high-quality components and a fanless heat dissipation design, it has a wide operating temperature range (-25℃~+70℃) and a mean time between failures (MTBF) of ≥ 150,000 hours, meeting the long-term continuous operation requirements of industrial systems.

Seamless Integration and Flexible Expansion

It supports module cascade expansion. Multiple AI835A modules can be added through the rack expansion interface, with a maximum expandability to 64 analog input channels, adapting to the multi-measurement point signal acquisition needs of large-scale industrial systems.

Intelligent Diagnosis and Fault Early Warning

Built-in with channel calibration function, it can perform zero and full-scale calibration via software and supports automatic calibration with standard signal sources, simplifying the calibration process and ensuring the stability of measurement accuracy during long-term operation.

Full-scenario Adaptability and Convenient Installation

III. Technical Parameters

| Category | Specific Parameters |

|---|---|

| Product Type | High-performance Analog Input Module (Advant OCS/AC800M Series) |

| Part Number | 3BSE051306R1 |

| Model Designation | AI835A |

| Core Functions | Multi-channel analog signal acquisition, signal conditioning, data transmission, fault diagnosis |

| Channel Configuration | 8 differential input channels, mutually isolated between channels |

| Supported Signal Types | Current: 4~20mA, 0~20mA (sourcing/sinking optional); Voltage: 0~10V, ±10V, 0~5V, ±5V |

| Measurement Accuracy | ±0.05% FS (25℃); Annual drift ≤ ±0.01% FS |

| Sampling Performance | Sampling rate: 100Hz per channel (simultaneous sampling for all channels); Filter coefficient: 0.1~100Hz programmable |

| Isolation Performance | Inter-channel isolation: ≥ 500VAC; Module-to-backplane isolation: ≥ 250VAC; Isolation type: Electrical isolation |

| Power Supply Parameters | Supply voltage: Provided by AC800M rack (5VDC/24VDC, depending on rack model); Power consumption: Typical 3W |

| Environmental Adaptability | Operating temperature: -25℃~+70℃; Storage temperature: -40℃~+85℃; Humidity: 5%-95% (non-condensing); Vibration resistance: 2g (10-500Hz) |

| Protection Performance | Protection rating: IP20 (rack-mounted); Electromagnetic compatibility: Complies with IEC 61000-4 standard; Certifications: CE, UL, CSA |

| Physical Parameters | Dimensions (W×H×D): 210mm×140mm×32mm; Weight: Approx. 0.5kg; Mounting method: AC800M rack installation |

| Software Compatibility | Programming software: Control Builder M; Supports channel parameter configuration, calibration, and diagnosis functions |

| Service Life | MTBF ≥ 150,000 hours (at 25℃) |

| Application Scenarios | Petrochemical engineering, power systems, metallurgical industry, intelligent manufacturing, water treatment, process control |

IV. Working Principle

The core working logic of ABB AI835A 3BSE051306R1 is "Signal Acquisition → Conditioning & Filtering → Analog-to-Digital Conversion → Data Transmission → Status Diagnosis", with the specific process as follows:

- Signal Acquisition: The 8 differential input channels simultaneously receive analog signals (current/voltage) output by field sensors. The isolation design between channels avoids mutual signal interference and ensures the integrity of raw signals.

- Conditioning & Filtering: The collected analog signals are amplified and buffered by the built-in signal conditioning circuit, then filtered for high-frequency interference and noise by the programmable digital filter, optimizing signal stability according to field conditions.

Analog-to-Digital Conversion: The conditioned analog signals are converted into 16-bit digital signals by the high-precision ADC (Analog-to-Digital Converter), with a conversion accuracy of ±0.05% FS, ensuring that the digital signals can accurately restore the original analog signals.

- Data Transmission: The digital signals are transmitted to the AC800M controller via the rack backplane bus, supporting real-time data transmission and batch data upload, with a transmission delay ≤ 1ms, meeting the real-time requirements of the control system.

- Status Diagnosis: It monitors the channel signal status and module working status throughout the process. If signal open circuit, short circuit, over-range, or module fault is detected, it immediately generates a fault code and uploads it to the controller, while marking the abnormal channel data to ensure the control system receives reliable data.

V. Operation Guide

1. Installation Steps

Installation Environment

Mechanical Installation

- Confirm that the equipment model (AI835A) and part number (3BSE051306R1) meet the design requirements. Check that the module has no appearance damage, no terminal oxidation, and no loose interfaces. Align the module with the AC800M rack guide rail, push it smoothly along the rail until the buckle locks, ensuring the module is fully in contact with the rack backplane.

- Pay attention to the module orientation during installation to ensure the wiring terminals face the correct direction (facilitating wiring operations). When installing multiple modules, install them in sequence according to the rack slot order. No additional heat dissipation space is required between modules (fanless design).

Wiring Operation

- Turn off the main power supply of the control cabinet. Connect the sensor signal wires to the module terminals according to the wiring diagram. Distinguish the positive and negative poles for current signals (for 4~20mA signals: positive to terminal "+", negative to terminal "-"), and pay attention to measuring range matching for voltage signals.

- Use double-shielded cables for signal wires, with the shield layer grounded at one end (ground resistance ≤ 4Ω). Separate analog cables from digital cables with a spacing of ≥ 10cm to avoid electromagnetic interference. If the cable length exceeds 100 meters, select cables with better shielding performance or install signal repeaters.

2. System Configuration

Initialization Settings

- Power on the rack, establish a connection with the AC800M controller through Control Builder M software, and identify the AI835A module (the controller automatically identifies the module model and address).

- Configure channel parameters: Select the signal type (current/voltage), measuring range, and filter coefficient for each channel, set the over-range alarm threshold and open-circuit detection function, save the configuration and download it to the controller.

Channel Calibration

- If measurement accuracy calibration is required, connect a standard signal source (such as a standard current source 4~20mA, standard voltage source 0~10V), start the channel calibration function in Control Builder M software, complete zero calibration and full-scale calibration in sequence, and the calibration data will be automatically stored inside the module.

- Verify after calibration: Input different standard signal values, check whether the deviation between the measured value displayed by the software and the standard value is within the range of ±0.05% FS to ensure the calibration effect.

3. Operation and Maintenance

Status Monitoring

- Real-time monitor the module working status through Control Builder M software: power supply status, channel data, fault alarm information, and check whether each channel has abnormalities such as over-range and open circuit.

- Regularly compare the measured data with the actual on-site parameters. If the data deviation exceeds the standard, promptly check the sensors, signal wires, or recalibrate the channels.

Regular Maintenance

- Monthly: Clean the dust on the module surface and inside the rack with dry compressed air; check whether the wiring terminals are loose or oxidized, re-tighten loose terminals, and wipe oxidized contacts with alcohol cotton pads; view the module self-diagnosis log through software to troubleshoot potential faults.

- Every 6 Months: Re-calibrate key channels to verify measurement accuracy; check whether the module is firmly connected to the rack, test the hot-swapping function if necessary; back up channel configuration parameters and calibration data.

- Annually: Perform a full-function test, simulate signal acquisition under different working conditions to verify the module's stability in high and low temperature environments; check whether the internal components of the module have signs of aging, and contact after-sales service for professional testing if necessary.

4. Common Fault Troubleshooting

| Fault Phenomenon | Possible Causes | Troubleshooting Methods |

|---|---|---|

| No data output from all channels | Incorrect module installation, rack power supply failure, module fault | Reinstall the module to ensure good contact with the backplane; check the rack supply voltage; test with a spare module |

| Abnormal/no data from a single channel | Sensor fault, signal wire open/short circuit, incorrect channel configuration | Test the sensor output signal; use a multimeter to check the continuity of the signal wire; verify the channel signal type and measuring range configuration |

| Excessive data fluctuation | Signal interference, excessively small filter coefficient, unstable sensor | Optimize cable routing (enhance shielding and grounding); increase the filter coefficient; check the sensor installation and working status |

| Measurement accuracy deviation exceeding standard | Uncalibrated channel, lost calibration data, standard signal source fault | Re-calibrate the channel; restore the backed-up calibration data; check the accuracy of the standard signal source |

| Module alarm "channel short circuit" | Signal wire short circuit, sensor short circuit, incorrect terminal wiring | Troubleshoot whether the signal wire is short-circuited; test whether the sensor is normal; verify the terminal wiring is correct |

| Module cannot be recognized by the controller | Improper module installation, rack interface fault, module hardware fault | Reinstall the module; check whether the rack slot is damaged; test with a replacement module |